WHAT IS ITLASER MARKING

3 min read

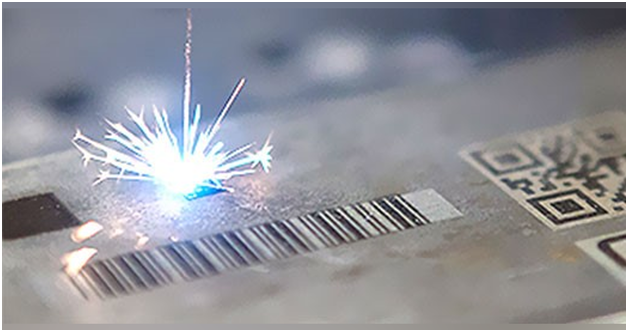

In its simplest form, laser marking is a permanent process that creates a mark on a surface using a concentrated beam of light. Laser marking can be done with various laser machines, including a pulsed, continuous-wave, green, or UV laser machine. These are the most popular types of laser marking:

Laser marking is easy to automate and can be done at high speeds. Permanent traceability marks can also be left on various materials, including steel, titanium and aluminum, copper, and ceramic. Parts and products may be marked with text (including part numbers and serial numbers), machine-readable data (barcodes, unique ID codes, 2D Data Matrix code codes), or graphics.

LASER MARKING: HOW IT WORKS

Laser marking uses a concentrated beam of light to mark a material’s surface. The beam’s interaction with it alters the material’s surface. Laser marking machines can create high-quality, high-contrast marks on any surface by focusing their laser beam only on a specific area. Laser marking is ideal for applications that require precision and permanence.

THE SCIENCE OF LASERS

The acronym laser stands forLight Amplification by the Stimulated Emitting of Radiation. Laser beams begin with an atom being stimulated to emit light particles. Laser marking areas can be created by concentrating the light. The wavelength or nanometers (NM) measure the energy released. The higher the wavelength, the more influential the laser beam. For example, a UV laser marker, which has a wavelength of around 355NM, offers a lower power for marking heat-sensitive materials such as plastic and glass. The UV laser marker and other machines belonging to the “cold laser” group emit less energy to be used for organic or soft products. On the other hand, a fiber laser operates at 1070NM, delivering significantly higher power to mark more complex materials, such as metal.

Laser marking is more cost-effective than other permanent marking processes like printing or labeling and requires less maintenance. For maximum system productivity and uptime, our team offers reliable and fast customer support. This includes a two-hour response time and free samples.

HOW TO USE A LASER-MARKING MACHINE

There are many types of laser marking systems, and each one works differently. The correct process to use the machine also depends on the material you’re working with and your application. MECCO offers a list of resources to help you operate your device and troubleshoot any issues, from how-to videos to detailed documentation.

It is essential to adhere to all safety guidelines when using any laser marking machine. Thanks to various preventative measures, including safety enclosure options, laser marking is a relatively safe process.

USE A LASER MARKER TO GET THE BEST BENEFITS

Laser marking can bring many benefits to manufacturers, including part identification and branding and complete traceability that allows them to trace and track parts from cradle to grave. Laser marking machines can be used to direct part marking. These marks are durable and easily readable. These high-quality marks produce:

- Increased operational efficiency and productivity, with less downtime and waste

- Transparency and accountability throughout the supply chain

- Reduced costly threats like quality and counterfeiting

- Conformance to industry regulations