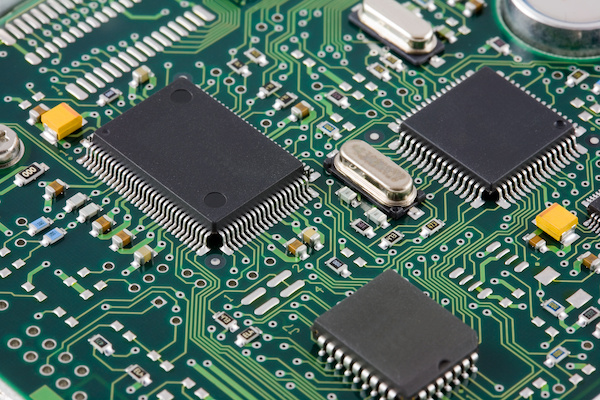

Printed Circuit Board

Printed circuit forums (PCBs) are the foundational constructing block of maximum present day digital gadgets. Whether easy unmarried layered forums used to your storage door opener, to the six layer board to your clever watch, to a 60 layer, very excessive density and excessive-pace circuit forums utilized in incredible computer systems and servers, published circuit forums are the muse on which all the different digital additives are assembled onto.

Semiconductors, connectors, resistors, diodes, capacitors and radio gadgets are installed to, and “talk” to each other via the PCB.

PCB’s have mechanical and electric attributes that lead them to best for those packages. Most PCB’s synthetic withinside the World are inflexible, more or less 90% of the PCB’s synthetic nowadays are inflexible forums. Some PCB’s are bendy, permitting the circuits to be bent and folded into shape, or on occasion they’re used in which the bendy circuit will continue to exist loads of heaps of flex cycles, with none smash withinside the circuits. These bendy PCB’s include more or less 10% of the market. A small subset of those forms of circuits are known as inflexible flex circuits, in which one a part of the board is inflexible – best for mounting and connecting additives, and one or greater elements are bendy, offering the benefits of bendy circuits indexed above.

A hastily rising PCB generation, break free those above, is known as published electronics – usually very easy, very low fee, circuits that lessen digital packaging fee to the extent that digital answers may be evolved to remedy troubles in no way taken into consideration before. They are frequently utilized in electronics for wearable packages, or disposable digital gadgets – commencing many possibilities for innovative electric designers.

Printed circuit board

Conventional PCB’s may be as easy as a unmarried layer of circuitry or can visit fifty layers or greater. They include electric additives and connectors connected thru conductive circuits – normally copper, with the reason of routing electric indicators and electricity inside and among gadgets.

PCB’s have been evolved withinside the early twentieth century however has had a endured escalated improvement in generation on account that then. The development and large adoption of generation in PCBs has paralleled the speedy development in semiconductor packaging generation and has enabled enterprise specialists to put money into smaller and greater green electronics.

Founded in 1977, Printed Circuits LLC has on account that comes to be a ground-breaking published circuit board manufacturer. Originally production all forms of PCB’s, they drove in the direction of specialization in inflexible flex and bendy circuit production withinside the mid 1990’s. Our wide choice of PCB designs, allows us to serve a huge variety of industries across the world, together with army, clinical, aerospace, pc, telecommunications, and instrumentation. Here we offer a complete evaluation of published circuit forums to offer applicable history facts for what we do.

Why Are Printed Circuit Boards Used?

Printed circuit Board manufacturer compared to conventional stressed circuits, PCBs provide some of benefits. Their small and light-weight layout is suitable to be used in lots of present day gadgets, at the same time as their reliability and simplicity of upkeep healthy them for integration in complicated systems. Additionally, their low fee of manufacturing makes them a fantastically fee-powerful option.

These traits are a number of the motives PCBs discover utility throughout industries, together with inside the following markets:

Medical

Medical electronics have notably benefited from the advent of PCBs. The electronics in computer systems, imaging systems, MRI machines and radiation device all maintain to improve in generation from the digital functionality in PCB’s.

The thinner and smaller length of bendy and inflexible flex PCBs permits for the manufacture of greater compact and light-weight clinical gadgets, which includes listening to aids, pacemakers, implantable gadgets, and virtually tiny cameras for minimally invasive procedures. Rigid-flex PCBs are a in particular best answer while seeking to lower the scale of complicated clinical gadgets, as they get rid of the want for the flex cables and connectors that take in treasured area in greater tricky systems.

Aerospace

Rigid, bendy and inflexible flex PCBs are generally hired withinside the aerospace enterprise for device panels, dashboards, flight controls, flight control and protection systems. The developing wide variety of advances in aerospace generation have extended the want for smaller, greater complicated PCBs to be used in aircraft, satellites, drones, and different aerospace electronics. Flexible and inflexible flex circuits provide brilliant sturdiness and challenge survivability because of the removal of connectors. This makes them appropriate to be used in excessive-vibration packages, at the same time as their small and light-weight layout reduces the general device weight and, consequently, gasoline intake necessities. For packages in which dependability is paramount, they function a fantastically dependable answer.

Military

In the army sector, PCB’s are utilized in device regularly uncovered to heavy impact, surprise and vibration packages, which includes army vehicles, ruggedized computer systems, present day weapons, and electronics systems (e.g., robotics, guidance, and concentrated on systems). As army generation advances to satisfy converting purchaser demand, greater device integrates superior automated generation, requiring each the electric and mechanical overall performance this is inherent in flex and inflexible flex packaging. These forms of digital packaging can resist heaps of kilos of g-pressure without failure.

Inflexible flex forums are used withinside the Bell Boeing helicopters

Industrial and Commercial

The use of PCBs in business and business electronics has revolutionized the whole lot from production to Supply Chain control – growing facts, automation and efficiency. In general, they’re a dependable method of directing device in more and more automatic facilities, improving manufacturing at the same time as lowering exertions costs. Flexible and inflexible flex PCB’s allow producers to provide more and smaller and lighter merchandise with more capability and plenty better reliability, which includes drones, cameras, cellular electronics, and ruggedized computer systems.